A manufacturing plant was a few months away from a $110 million capital project startup when it discovered there was insufficient product storage capacity for their major expansion. This would have bottlenecked production resulting in lost productivity and revenue.

How can you be prepared for startup? Begin the process early to ensure operational readiness with a Site Readiness Assessment (SRA).

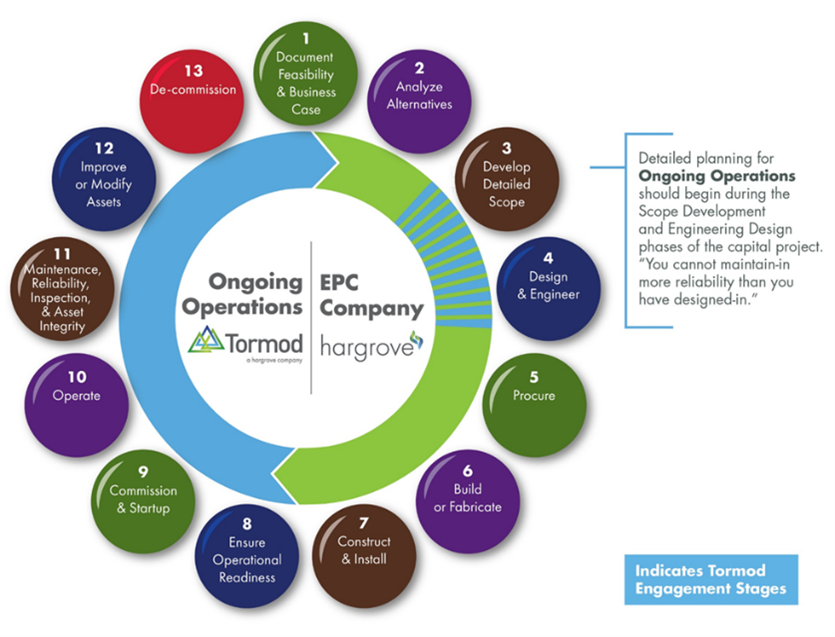

Ensuring Operational Readiness is the 8th stage in the Asset Life Cycle, completed by effectively utilizing the Site Readiness Assessment (SRA) tool. Tasks associated with preparing for the SRA should begin as early as Stage 4 (Design and Engineer) and should continue until the site is fully prepared for the upcoming change. Completion of tasks/items generated from the SRA may extend as far upstream of Stage 9 (Commissioning and Startup) to provide the site team with confidence that they possess The Technical Right To Succeed in operating new assets and processes. This same logic applies to turnarounds focused primarily upon Maintenance & Repair tasks because change can occur from any tasks that intervene upon normal asset operation.

What is a Site Readiness Assessment?

An SRA, also known as an Operational Readiness Assessment, is a disciplined, structured, documented tool that is used to objectively assess and verify all stakeholder groups are properly prepared to ensure the safe, compliant, high-quality, on-time, and on-budget performance of a major project or major turnaround (also referred to as an outage). Any event that creates, or has the potential to create significant change in the performance of a site will benefit from a professionally executed SRA.

An SRA is a structured, documented assessment consisting of 900 +/- questions, tailored for the specific site and project. Questions are separated by subject area, normally by site department.

Issues identified and corrected thanks to a disciplined SRA include a lack of a Bills of Materials in the Computerized Maintenance Management System (CMMS), missing or insufficient training for operators, maintenance mechanics, quality testers, and other plant personnel, missing Material Safety Data information, and lack of new maintenance procedures or tools identified for new equipment.

An SRA can mitigate risk by ensuring all departments and functions are aligned with the requirements for a successful outcome and can maximize return on investment by adhering to the schedule and budget.

Stakeholder Groups

It is important for all stakeholder groups to be represented during an SRA. Stakeholder groups with input into the success or failure of a major project or turnaround include the following:

- Environmental compliance – new materials, wastes, regulations, monitoring, treatment processes

- Industrial Hygiene (safety) – new equipment with new hazards

- Plant Security – security, traffic, weighing, record keeping, hazardous materials, etc.

- Manufacturing – new or changed products, new training requirements

- Maintenance – new equipment, spare parts, maintenance techniques, inspection requirements

- Logistics – inbound and outbound shipment volumes, modes, and schedules

- Supply Chain – new suppliers, new materials, etc.

- Quality – new specifications, new customers, new testing methods

- Accounting & Finance – new accounts, new materials, changed prices, reporting changes

- Procurement – new materials, parts, tools, suppliers, contracts, foreign currency requirements

- Information Technology – new IT systems, network demands, data storage/reporting

- Human Resources – new people, new schedules, new roles, new labor rates, etc.

- Sales & Marketing – effects on inventory management and customer shipments

- Plant Employees – are they informed, trained, equipped, and prepared for the change?

- Plant Suppliers – are they given sufficient information to help with the change?

Conducting an SRA

Traditionally, two SRAs are performed: a “Baseline Assessment” and a “Final Assessment.” The agenda and methodology for both Baseline and Final Assessments are nearly identical.

Baseline Assessment

The Baseline Assessment should be performed 12-18 months prior to the major event (i.e. the startup of a major capital project or turnaround). The Assessment Team prepares the assessment questions, schedules times and locations to meet with the site’s subject matter experts and department leaders and visits the site for a period of 2-5 days, depending upon the size and complexity of the project/turnaround and the size of the assessment team.

The SRA team first conducts a series of interviews with subject matter experts in a small group setting. This is called “the conference room assessment.” Answers to questions from each subject area (stakeholder group) are documented in as much detail as possible. There may be unknowns during the Baseline Assessment, but these are important and documented.

When the initial interviews are completed, the SRA team goes into the field to complete the Field Verification phase of the assessment. Objective evidence from the field is documented alongside answers that were provided in the conference room interviews. Any gaps between “reported” and “field verified” information are documented to keep the entire team aligned and data-driven.

After documenting “as answered” and “as verified” conditions to 900 +/- questions, the SRA team compiles a detailed report showing the status of every question. Each question is part of a designated subject area or stakeholder group, so the report shows the current level of readiness of every stakeholder group. This data is provided in detail to help the team understand the current readiness level of every group.

The Baseline SRA is used to prioritize which identified gaps will be closed, who will be responsible for closing each item, and by when this will be completed. These decisions are documented via the Rolling Action Items List (RAIL).

Routine RAIL Update meetings should be conducted, documented, and communicated at least monthly during the 12-18 months that are available between the Baseline Assessment and the major event. If prioritized gaps are not being closed every month, Site Readiness is not being effectively managed.

Final Assessment

A Final Assessment, following the same methodology as the Baseline Assessment, is performed 2-3 months prior to the major event. Ideally, all previously prioritized and managed gaps are verified to be sustainably closed. If not, these gaps will be identified and highlighted to all stakeholders so action can be taken prior to the major event.

The Final Assessment also helps identify any new gaps that arose between the Baseline and Final Assessments. This is normal, especially for large, complex projects or turnarounds. As scope, schedule, and cost evolves, new gaps (sources of unreadiness) arise.

Working with an Experienced Team

Tormod’s Teammates conduct SRAs across multiple industries and bring best practices for the benefit of our clients. To learn more about how an SRA can help your project, turnaround, or major change initiative, contact us today.